Practical Food Innovation

TOP BV is the technical development partner specialised in practical innovation for the food industry. We are contracted by food producers and equipment manufacturers from all over the world to provide our services in designing unique innovations.

“Where creativity meets the palate, we design the future of your food.”

TOP BV provides highly practical solutions that are fit for smooth implementation. This effectively means we focus on the development of food products (NPD), production machines (engineering) and processes (including full factories) that are best suited to specific customer demands. We prefer to keep our R&D projects compact and to the point and operate from extensive expertise across a wide range of food categories. This predominantly includes hybrid and fully plant-based alternatives, meat, fish and dairy products, bakery goods, functional drinks, as well as convenience fruits and vegetables.

Our efficient development practises with short lead times and minimal bureaucracy will enhance your innovation capabilities and directly drive the growth of your core business. This is done by keeping project teams small and by having them operate like an agile task force assigned to your challenge. TOP BV has nearly two decades of experience and know-how that has been instrumental in creating strong win-win collaborations with a broad set of companies regardless of their size and history. Our design language, management effectiveness and development methods appeal to startups, and SME’s all the way to multinationals.

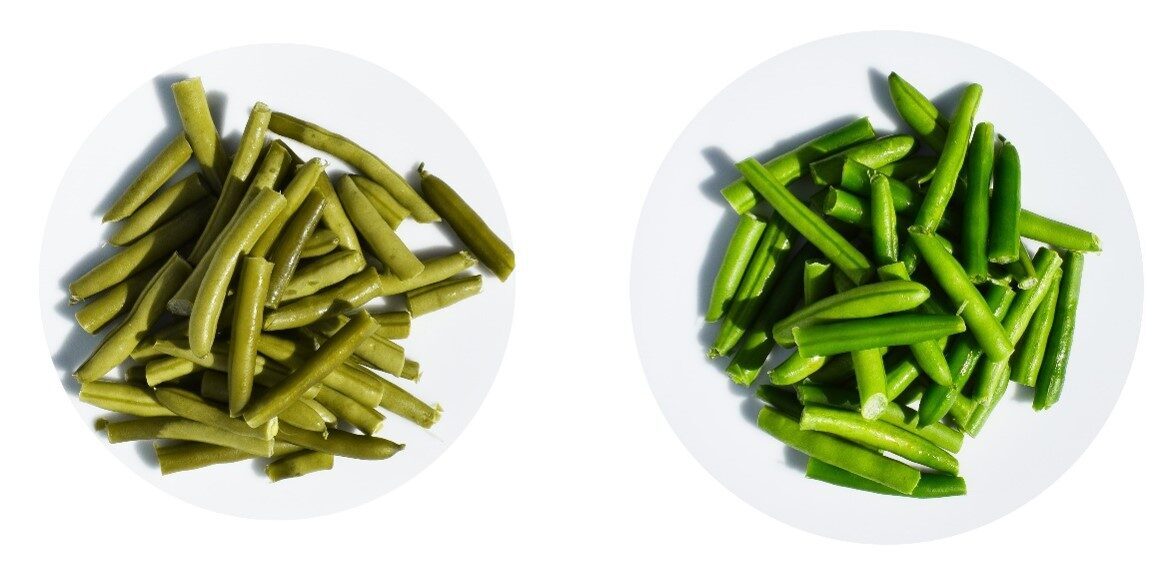

We can develop sustainable machines and production lines, and assist in both factory expansions as well as totally new constructions. We know food products have to meet with stringent safety requirements, which is always taken into account during our development work. In turn, reduced spoilage and extended shelf life also help to eliminate food waste. To that end our team is specialised in the use of various preservation technologies such as RF-inline/in-pack heating (Radio Frequent), cutting edge retort using Tetra Pak® Recarts or classic canning, AMAP and HPP (Pascalisation).

Lastly, we aim to assist in the valorisation of waste and co-streams where possible as part of our commitment to combating food waste. You are cordially invited to join our innovation journey on the way to a healthier and more sustainable planet.

Food product development

- New Product Development (NPD)

- Recipe reformulation

- Scale-up to industrial production

- Value engineering

- Shelf-life extension

Ingredient functionality

- Screening of functionality

- Benchmarking versus golden standards

- Performance in applications

- Recommendations for improvement

- Waste and co-stream valorisation

Process development

- Development of new process equipment

- Design of production lines

- Scale-up of process technologies

- Factory and pilot plant design

- Efficiency optimisation

Other services

- Project management

- Retort pilot testing (Tetra Recart® and cans)

- Texture and water activity analysis

- Brainstorming and ideation

- Quality assurance consultancy

- Troubleshooting